Bulimba Creek Sewer Upgrade - Stage 2 - Brisbane, Austrialia

Project Detail

Procurement Type: Design & Construct

Owner: Queensland Urban Utilities

Construction Cost: $55 million

NOMA´s client: Abergeldie - Obayashi JV

Design Period: 2016 – 2017

Construction Period: 2016 - 2018

Project Phase: Tender and Detailed Design

The Project

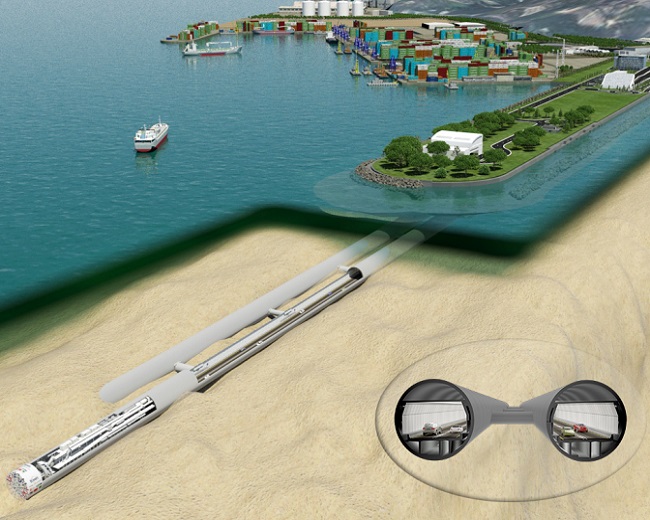

Queensland Urban Utilities (QUU) is upgrading the existing sewer network by constructing a tunnelled gravity sewer with an internal diameter of at least 1500mm and a length of 4.2km on a parallel alignment away from the alignment of the existing sewer between Wecker Road and old Cleveland Road.

The proposed pipe alignment commences immediately north of Wecker Road to a point north of Old Cleveland Road, and follows an alignment generally beneath Scrub Road. The tunnelling works is about 4229m. The mainline invert level will be at RL +8.2mAHD at Mansfield or southern end and reducing to RL -2.7mAHD at Carindale or northern end where it joins with the existing trunk sewer in parklands adjacent to Bulimba Creek. Surface levels along the proposed alignment range from about RL +12mAHD near Bulimba Creek at Mansfield, to about RL +60mAHD at the highest point at Scrub Road, and reducing to about RL +3mAHD at Carindale near Bulimba Creek. The mainline alignment will be up to 60m below the surface.

Abergeldie-Obayashi JV (AOJV) plans to construct the pipe jack tunnel with a Herrenknecht mini-TBM AVN1500TB. The machine excavation diameter will be 1850mm. A bentonite slurry fluid transport system is adopted to enable the application of a positive face pressure for ground/groundwater control, where necessary. The tunnel will be lined with Glass fibre reinforced plastics (GRP) pipes with an OD of 1780mm (SN 55,000).

Key Aspects of the Project

- MH 4 – f7.5m launch shaft in residual soil to slightly weathered (SW) meta-sandstone is supported with rock bolts or mesh reinforced shotcrete ring. Two stub tunnels at the shaft base supported by rock bolts and shotcrete for double direction pipe jacking

- MH 4A – Reception Shaft in residual soil or fault zone is supported by mesh reinforced shotcrete ring or in DW meta-siltstone supported by rock bolts

- MH 5 – f7.5-9.0m Launch Shaft (with bell-out) in residual soil to SW meta-sandstone is supported with rock bolts or mesh reinforced shotcrete ring

- MH 6 – f6.5m reception shaft in alluvium underlain by extremely weathered (XW) sandstone is supported by pre-cast segmental lining caissons

- MH 7T – 10.1m x 5.6m rectangle launch shaft in alluvium (clay, sility sand and gravel) underlain by XW mudstone is supported by steel sheet piles and walers

Scope of Works

NOMA Consulting was engaged by AOJV to carry out the detailed design of the following design aspects:

- Review of the geological/geotechnical conditions

- Assessment of TBM pipe jacking force and assessment of intermediate jacking stations required

- MH 4 – Launch Shaft, including shaft wall support and two thrust blocks with soft eyes

- MH 4A – Reception Shaft, including shaft wall support and two stub tunnel supports

- MH 5 – Launch Shaft, including shaft wall support and two thrust blocks with soft eyes

- MH 6 – Reception Shaft

- MH 7T – Initial Launch Shaft, including shaft wall support, one thrust block and one soft eye design

- Addressing comments from site and verification of design modifications

- Construction support